What Is Quality Concrete?

To fully appreciate the benefits of Fly ash in concrete, the basics of producing exceptional concrete must be understood. Concrete is a composite material,

which essentially consists of two components: aggregates and cementitious paste. To produce exceptional concrete, it is extremely important to have a smooth gradation of material from rock down to the finest particles(in other words, a good mix of particle sizes, so that the largest practicable rock fills the majority of the volume, while the progressively smaller rock and sand fill the voids left between the larger particles). Ideally, it is best to have as much volume as possible filled with strong, Durable aggregate particles, with enough paste (comprised of as much CSH and as little lime as possible) to coat every particle. Also, voids should not be present in the paste unless they are specifically provided as microscopic entrained air bubbles to provide durability in freeze-thaw environments.

In real life, though, economics and local aggregate sources dictate the quality of materials used. The result is that excess voids often exist between the aggregate particles that must now be filled by paste and air. The challenge becomes producing an appropriate amount of the best possible quality paste, so that the resulting hardened paste will fill the excess voids with durability and strength approaching that of the aggregates.

^ Top ^

How Fly Ash Contributes to Concrete Durability and Strength

Most people don’t realize that durability and strength are not synonymous when talking about concrete. Durability is the ability to maintain integrity and strength over time. Strength is only a measure of the ability to sustain loads at a given point in time. Two concrete mixes with equal cylinder breaks of 4000 psi at 28 days can vary widely in their permeability, résistance to chemical attack, resistance to cracking and general deterioration over time___all of which are important to durability.

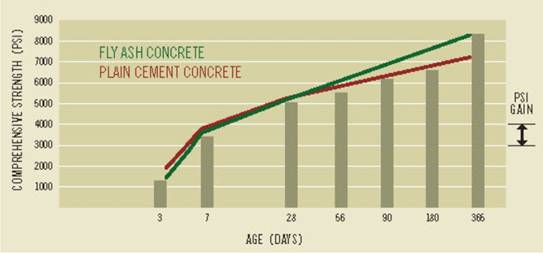

Cement normally gains the great majority of its strength within 28 days, thus the reasoning behind specifications normally requiring determination of 28-day strengths as a standard. As lime from cement hydration becomes available (cements tend to vary widely in their reactivity), it reacts with fly ash.Typically, and concrete made with fly ash will be slightly lower in strength than straight cement concrete up to 28 days, equal strength at 28 days, and substantially higher strength within a year’s time. Conversely, in straight cement concrete, this lime would remain intact and over time it would be susceptible to the effects of weathering and loss of strength and durability.

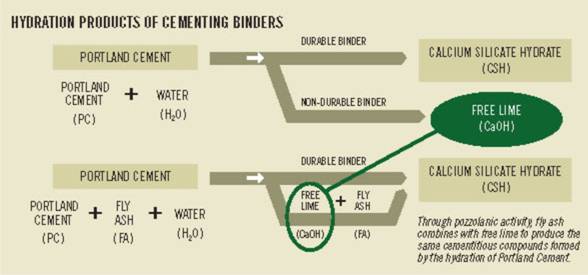

As previously described, the paste is the key to durable and strong concrete, assuming average quality aggregates are used. At full hydration, concrete made with typical cements produces approximately ¼ pound of non-durable lime per pound of cement in the mix. Most people have seen concrete or masonry walls or slabs with the white, chalky surface coating or streaks called efflorescence. Efflorescence is caused by the face of the concrete being wetted and dried repeatedly or by the movement of water vapor from the damp side of the concrete to the dry side through the capillaries (voids), drawing out the water soluble lime from the concrete, block or mortar. A typical 5 sack concrete mix having 470 pounds of cement per cubic yard has the potential of producing 118 pounds of lime. Fly ash chemically reacts with this lime to create more CSH, the same “glue” produced by the hydration of cement and water, thereby closing off the capillaries that allow the movement of, moisture through the concrete. The result is concrete that is less permeable, as witnessed by the reduction in efflorescence.

^ Top ^

How Fly Ash Contributes to Concrete Workability

First, fly ash produces more cementitious paste. It has a lower unit weight, which means that on a pound for pound basis, fly ash contributes roughly 30% more volume of cementitious material per pound versus cement. The greater the percentage of fly ash “ball bearings” in the paste, the better lubricated the aggregates are and the better concrete flows.

Second, fly ash reduces the amount of water needed to produce a given slump. The spherical shape of fly ash particles and its dispersive ability provide water-reducing characteristics similar to a water-reducing admixture. Typically water demand of a concrete mix with fly ash is reduced by 2% to 10 % depending on a number of factors including the amount used and class of fly ash.

Third, fly ash reduces the amount of sand needed in the mix to produce workability. Because fly ash creates more paste, and by its shape and dispersive action makes the paste more “slippery” the amount of sand proportioned into the mix can be reduced. Since sand has a much greater surface area than larger aggregates and therefore requires more paste, reducing the sand means the paste available can more efficiently coat the surface area of the aggregates that remain.

Evidence of the contribution fly ash makes to workability includes:

- Lightweight concrete including fly ash is much easier to pump.

- Finishers notice the “creamier” texture when working. They also see reduced “bug holes” and segregation when stripping forms. Slip form pavers eliminate rock pockets and voids in an otherwise harsh, no-slump paving mix.

^ Top ^

How Fly Ash Protects Concrete

An extremely important aspect of the durability of concrete is its permeability. Fly ash concrete is less permeable because fly ash reduces the amount of water needed to produce a given slump, and through pozzolanic activity, creates more durable CSH as it fills capillaries and bleeds water channels occupied by water-soluble lime (calcium hydroxide).

Fly ash improves corrosion protection. By decreasing concrete permeability, fly ash can reduce the rate of ingress of water, corrosive chemicals and oxygen-thus protecting steel reinforcement from corrosion and its subsequent expansive result.

Fly ash also increases sulfate resistance and reduces alkali-silica reactivity. At this point a distinction between Class C and Class F fly ashes needs to be made. While both improve the permeability and general durability of concrete, the chemistry of Class F ashes has proven to be more effective in mitigating sulfate and alkali-silica expansion and deterioration in concrete. Some Class C fly ashes have been used to mitigate these reactions, but must be used at higher rates of cements replacement.

Fly ash in concrete can reduce sulfate attack in two additional ways:

- Fly ash reduces calcium hydroxide, which combines with sulfates to produce gypsum. Gypsum is a material that has greater volume than the calcium hydroxide and sulfates that combine to form it, causing damaging expansion.

- Aluminates in the cement also combine with sulfates to form expansive compounds. By replacing cement, the amount of available aluminates is reduced, thereby lowering the potential for this type of expansive reaction.

In reducing alkali-silica reactivity, fly ash has the ability to react with the alkali hydroxides in Portland cement paste, making them unavailable for reaction with reactive silica in certain aggregates. Certain studies suggest that greter than 30% replacement with fly ash for cement has a dramatic effect in combating this expansive reaction.

^ Top ^

How Fly Ash Reduces Heat of Hydration in Concrete

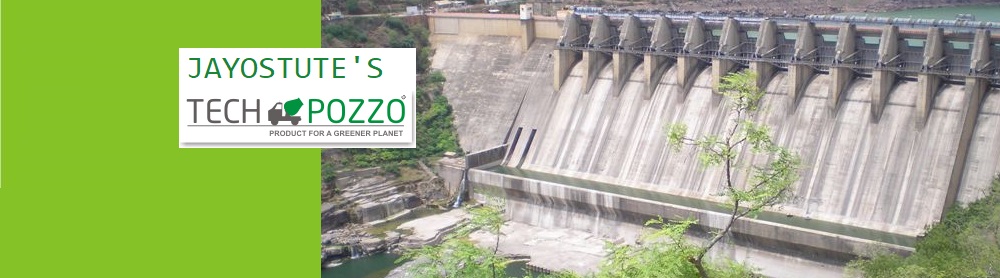

The hydration of cement is an exothermic reaction. Heat is generated very quickly, causing the concrete temperature to rise and accelerating the setting time and strength gain of the concrete. For most concrete installations, the heat generation is not detrimental to its long-term strength and durability.However, many applications exist where the rapid heat gain of cement increases the chances of thermal cracking, leading to reduced concrete strength and durability. In these applications, replacing large percentages of cement with fly ash (fly ash generates only 15 to 35 percent as much heat as compared to cement at early ages) can reduce the damaging effects of thermal cracking.

While the first structures to apply this concept in earnest were hydroelectric dams built in the 1930s and 1940s with 40% to 50% cement replcement, warm weather concreting and the risk of thermal cracking is a problem that exists today for all concrete. Warm weather will naturally raise the temperature of concrete aggregates, which make up the majority of the mass in concrete. This natural heating of the aggregates, coupled with solar heating at the construction site, can cause even thin concrete slabs to suffer the damaging effects of thermal cracking along with finishing difficulties caused by rapid uncontrolled setting. Replacing 20% to 35% of the cement for “everyday” concrete in warm conditions will help reduce thermal cracking and provide the time needed to obtain the desired finish.

^ Top ^